Titanium Dioxide Coatings: Properties and Applications

Titanium dioxide (TiO2) may not be a household name, but its applications are present in many aspects of daily life. Renowned for its versatility, TiO2 coatings are vital in numerous industries, ranging from construction to healthcare. This blog delves into the core properties that make titanium dioxide coatings indispensable and their wide-ranging applications that are shaping technology today.

Properties of Titanium Dioxide

Titanium dioxide is a standout material, boasting a unique combination of properties that make it an ideal component for everyday products including cosmetics, food additives, coatings and more. The more salient properties of TiO2 include:

- High Refractive Index: TiO2 has a high refractive index (2.25 @ 550-nm), making it ideal for fabricating dielectric mirrors used in laser optics.

- UV Protection: TiO2 efficiently absorbs ultraviolet (UV) light, providing excellent UV blocking properties. For this reason, many sunscreen and UV blockers utilize TiO2 as a key ingredient.

- Photocatalytic Activity: When TiO2 absorbs UV light, it generates an electron-hole pair that subsequently catalyzes chemical reactions. This effect is useful for self-cleaning surfaces, and antimicrobial coatings.

- Chemical Stability: TiO2 is chemically stable and resistant to corrosion, which makes it suitable for use in harsh environments.

- Non-Toxicity: TiO2 is generally considered non-toxic and is safe for use in food contact materials and cosmetics.

Applications of Titanium Dioxide Coatings

The real-world applications of TiO2 coatings are as fascinating as they are diverse. Self-cleaning surfaces such as windows and exterior paints capitalize on its photocatalytic properties to break down pollutants. Hospitals and food processing plants utilize TiO2’s antimicrobial properties to maintain sterile environments. In consumer products, TiO2‘s ability to absorb ultraviolet light is why it’s a key ingredient in sunscreens and is also used to protect plastics and textiles from UV degradation. Moreover, its role in photocatalytic purification systems is instrumental in advancing environmental sustainability by purifying air and water. The high refractive index of TiO2 makes it ideal for enhancing the efficiency of optical components like mirrors and fiber optics.

Titanium Dioxide Coatings by Platypus Technologies

At Platypus Technologies, we fabricate thin film coatings of TiO2 via reactive e-beam evaporation, which is a vacuum process incorporating high-energy oxygen. In e-beam evaporation, an energetic beam of electrons impinges upon a block of pure titanium dioxide, causing ejection of partially oxidized titanium oxide molecules. Meanwhile, a stream of high-purity oxygen flows into the vacuum at high temperature. During the travel from the source to the substrate, the titanium oxide reacts with the oxygen and re-oxidizes to TiO2. This TiO2 deposits onto the substrate, which is heated at 250 °C to improve the adhesion and optical properties of the final coating.

The image above shows an example of a TiO2 film coated onto a microscope glass slide. The image demonstrates the uniformity and quality of the coating process, which are important parameters in industrial applications such as optics, semiconductors, and coatings for scientific research. The coated glass appears translucent with a hint of purple hue, indicative of light interference effects. This effect is directly related to the optical properties of the TiO2 coating, where certain wavelengths of light interfere constructively and destructively as they reflect off the different interfaces of the coating, leading to the observed coloration.

Spectroscopic Analysis of Titanium Dioxide Thin Films

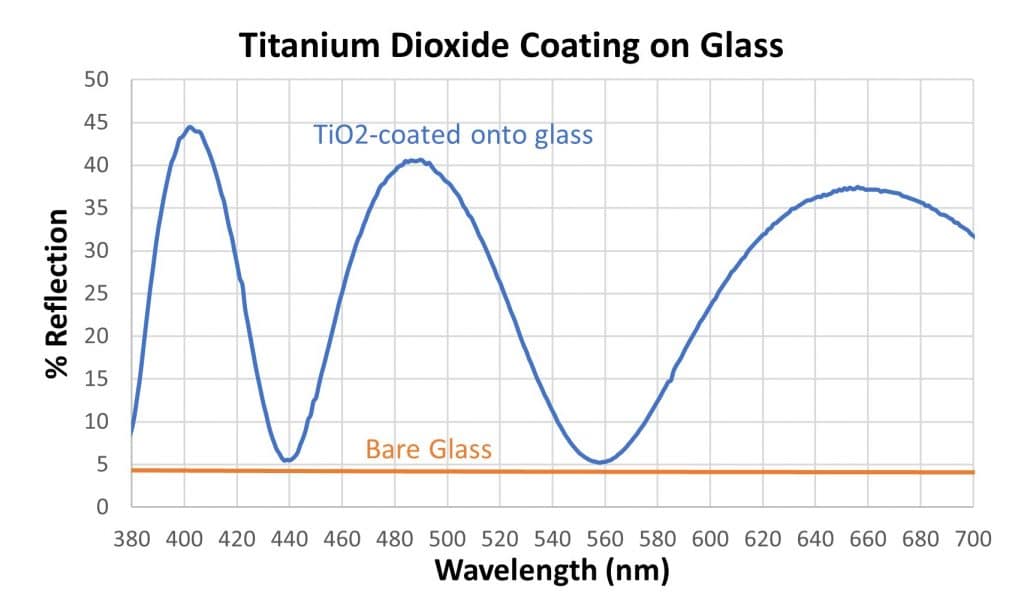

Spectroscopic analysis of the TiO2-coated glass slides provides further insight on the optical properties of the TiO2 film. The image below shows the percentage of light reflection over the visible light spectrum, from 380 nanometers (nm) to 700 nm, for the glass slide coated with TiO2 compared to bare glass.

Notice the spectra for the TiO2-coated glass (blue line) exhibits three (3) pronounced peaks, indicating wavelengths where the reflection (R) is significantly higher than the rest of the spectrum. The first peak occurs at 402-nm (R = 44.51%), the second peak at 490-nm (R = 40.67%), and the third peak occurs at 656-nm (R = 37.49%). The wavelengths at which the maxima appear depend only on the thickness of the film and the refractive index of the coating. Thus, we use this information to calculate that the deposited film was 378-nm.

The reflection spectrum for the uncoated, bare glass is depicted as a flat line (orange line), which stays consistently low, at ~4%, showing that bare glass reflects a much lower percentage of visible light across the spectrum compared to the TiO2-coated glass.

The Science Behind TiO2 Coatings for Optics

The science of TiO2 coatings is grounded in its interaction with light. When applied as a thin film, TiO2 creates an interference effect, observable as shimmering colors, a result of different light wavelengths reflecting off its surface. Analyzing the reflection spectrum of TiO2 coatings reveals how they can be tailored to specific applications, such as maximizing light reflectance at wavelengths for improved optical performance. By changing the thickness of the TiO2 film, it is possible to change the wavelength at which maximum reflection is observed.

Conclusion

Titanium dioxide coatings offer an extraordinary combination of properties that make them invaluable across a spectrum of applications. From self-cleaning windows to enhanced optical devices, TiO2 is quietly revolutionizing the way we approach materials and their capabilities. As research continues to unlock new potentials, the future of TiO2 coatings is as bright as the surfaces they protect. Engage with the material of the future—consider the impact that TiO2 coatings could have on your next project.